Weishaupt burners, ranging from 12 to 32000 kW, are known for their efficiency, low NOx emissions, reliability, longevity, and excellent return on investment. They are compatible with various gas and oil type fuels and offer dual fuel and Low NOx versions for most burner types. Some of their most notable features include burners with preheated combustion air, O2 trimming, VFD systems, and accessories approved by the FM Global standards.

Weishaupt offers flexible communications compatible with building management systems (BMS connection options), Interfacing with superordinate systems via eBus and Modbus, Optional protocol convertors (gateways) for connection to other bus systems, Direct connection over LAN / W-LAN & Remote monitoring made easy via tablet or laptop, etc.

WG5-40 compact gas burners

Rated outputs: (12.5-550 kW)

Download catalogue

WL5-40 compact oil burners

Rated outputs: (30 – 570 kW)

Download catalogue

WGL30-40 compact dual-fuel burners

Rated outputs: (70 – 550 kW)

Download catalogue

The millions of W-series burners that have already been installed are a reliable, safe, and economical source of heat for domestic and commercial heating and hot-water systems the world over, as well as for countless industrial applications.

The burners, which are rated for outputs of up to 570 kW, are not only extremely compact but they are also equipped with the latest Weishaupt combustion technology Digital combustion management is a standard feature across the range and offers the highest degree of operational reliability and efficiency, thanks to its microprocessor-based monitoring and control of all burner functions.

WM 10 (20 – 1250 kW)

Download catalogue

WM 20 (80 – 3000 kW)

Download catalogue

WM 30 (350 – 6200 kW)

Download catalogue

WM 50 (750 – 12000 kW)

Download catalogue

WM10-30 with oil preheating

Download catalogue

WM10-50 Vertically fring

Download catalogue

The current range of Weishaupt monarch® burners embodies these virtues within an outstanding design that utilises the latest technology. The gas, oil, and dual-fuel burners are used to fire hot-water, steam, and water-tube boilers, as well as air heaters, and they do so not only reliably but also extremely quietly. Weishaupt was able to use its own aerodynamics testing facility – something unique in the industry – to develop a completely new air inlet geometry that facilitates the extraordinarily quiet and efficient operation of the burners.

Weishaupt digital combustion managers are included as standard with the latest monarch® burners, guaranteeing both low emissions and the extremely precise and continually reproducible dosing of fuel and combustion air. Furthermore, digital control of the burners opens up numerous opportunities for automation and control through integration with building management systems and bus networks.

The burners can also be equipped with variable speed drive and O2 trim to help increase efficiency even further – flexibility that pays for itself. Weishaupt’s WM-series monarch® burners offer a seamless range of outputs up to 12 MW.

This latest generation of these burners is particularly notable for efficiency, low emissions, and reliable operation.

WG40 (60 – 700 KW)

Download catalogue

WMG 10, 20 & 30 (85 – 5000 kW)

Download catalogue

For more than six decades, Weishaupt’s monarch® series burners have been used on a wide variety of heat generators and industrial plant, and their success has helped underpin Weishaupt’s outstanding reputation.

Their PLN-version burners stand ready for use in situations where the very lowest of emission levels are being demanded. PLN stands for Premix Low NOx – a system that combines premixing with surface-stabilised combustion.

A further advantage of this type of combustion system is that it can be used on appliances with particularly small combustion chambers, as well as with more typical boilers.

The WG40, WM-G10, WM-G20, WM-G30 burners cover, between them, an output range of 60-5000 kW. Weishaupt’s PLN-version premix burners also have similar turndowns to their forced-draught stablemates. The electronic compound regulation that is provided by the W-FM 50, W-FM 100, and W-FM 200 combustion managers can achieve turndown ratios of 7:1.

One substantial benefit of this technology is to be found in the combustion chamber requirements. These can be considerably smaller than those found in typical boilers.

The gas/air mix, which is under pressure, permeates the microweave alloy mat and combusts at its surface. The flame carpet thereby created has flame temperatures below 1200 °C and so the formation of thermal NOx is inhibited. NOx emission levels below 30 mg/kWh are now also a reality for medium-capacity burners.

Weishaupt WKmono-series burners (1200-17 000 kW)

Download catalogue

For more than six decades, Weishaupt burners have proven themselves on a wide variety of heat generators and process plant. Their success stems from a relentless demand for high- quality materials and workmanship, and uncompromising quality control standards.

Weishaupt continually establishes new benchmarks with its well- engineered products, facilitated by the ever-constant efforts of its own Research and Development Centre. Such efforts produced the WKmono 80, which shares its platform with the duobloc WK 80. The large 1200 to 17000 kW range of the WKmono 80, which is available in NR and multiflam® versions and is suitable for natural gas, LPG, and gas oil, is particularly impressive.

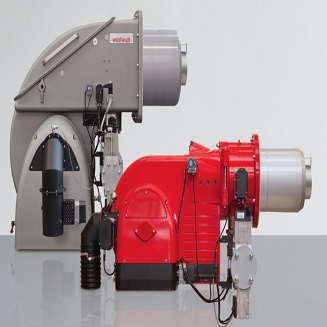

Weishaupt WK-series burners (up to 32000 KW)

Download catalogue

The WK-series burners are Weishaupt’s most powerful burners of all. They were designed especially for hard industrial use, with capacities of up to 32000 KW. The modular concept with an external fan facilitates a specific matching to all operating conditions. WK-series burners are available as gas, oil, and dual-fuel units.

Weishaupt WK-series burners are suitable for intermittent firing and continuous firing on LTHW boilers, HTHW boilers, Steam boilers, Air heaters, Thermal fluid heaters, Process applications.

Features to save energy and increase safety and reliability.

VSD provides several benefits. It facilitates a soft start of the burner fan, keeping the start current to a minimum, and matches the speed of the fan to combustion air volume during operation, which saves electrical energy and

reduces noise emissions.

O2 trim saves fuel by means of a continual and extremely efficient optimisation of the combustion air. The system is controlled by a Lambda probe, which continually measures the oxygen content of the flue gas.

Weishaupt marine-execution burners

Download catalogue

For decades, Weishaupt has designed and produced marine burners for a wide range of applications, such as auxiliary and hot-water boilers for ships or offshore installations. Weishaupt’s in-house Research and Development Centre is constantly working on innovative new developments. The burners are notable for their robust and compact design, and for being easy to install and service. Particular care was taken during development to ensure a maintenance-friendly design. The commitment to quality goes beyond the burner and its servicing. Weishaupt offers individual solutions for fuel trains and for the control of burners, boilers, and their services. Weishaupt is your one-stop shop for expertise.

Digital combustion management makes the operation of combustion plant both convenient and safe. All essential functions, such as flame monitoring and the regulation of fuel and air are affected and controlled with digital precision.

A Weishaupt burner for almost any fuel. There are various qualities of marine fuel oil (MFO). MARPOL 73/78 Annex I to VI regulates the use and the emission of sulphurous combustion products in certain sea areas. This has resulted in the production of non-standard, reduced-sulphur oils.

The ISO 8217 standard for marine fuels differentiates between distillate fuel oils(MGO) and residual fuel oils (RFO). The most important specifications limit the density viscosity, water content, and flash point of the oil.

MARPOL regulations stipulate that a sample of each fuel delivered must be available onboard. The fuel may only be used once the fuel specification (Bunker Delivery Note) has been approved by the test laboratory.

Weishaupt burners in marine execution aresuitable for use with marine fuel oils that are compliant with ISO 8217 2010-06-15 andISO 8217 2011-09 (please enquire regarding the suitability of other fuels).

For safety reasons, due to its low flash point of 45 °C, DMX-quality oil is not approved for combustion on board ships.

Weishaupt 4LN-version gas burners (with flue gas recirculation) WM-series, WKmono-series, and WK-series burners (700-23000 kW)

Download catalogue

Weishaupt 4LN-version gas burners are an innovative further development of patented multiflam® technology combined with flue gas recirculation.

At the heart of this further development of larger multiflam® burners lies a swirl body in the secondary air area and a longer flame on the primary diffuser. In combination with flue gas recirculation, the swirl body generates an intensive mixing of the fuel, air, and recirculated flue gas. The primary flame, which is adapted for high flue gas recirculation rates, ensures the flame remains stable at all stages of operation.

How does FGR work?

Flue gas recirculation has a particular effect on the formation of thermal NOx by reducing the oxygen concentration in each cubic metre of air. This results in increased air flow speed, which reduces the dwell time of the combustion gases in the hot reaction zone and lowers the flame temperature.